Production characteristics of graphite electrodes

1. Long production cycle. The production cycle of ordinary power graphite electrodes is about 45 days, the production cycle of ultra-high power graphite electrodes is more than 70 days, and the production cycle of graphite electrode joints that require multiple dipping is longer.

2. High energy consumption. The production of 1t of ordinary power graphite electrode requires about 6000kw·h of electricity, thousands of cubic meters of gas or natural gas, and about 11t of metallurgical coke particles and metallurgical coke powder.

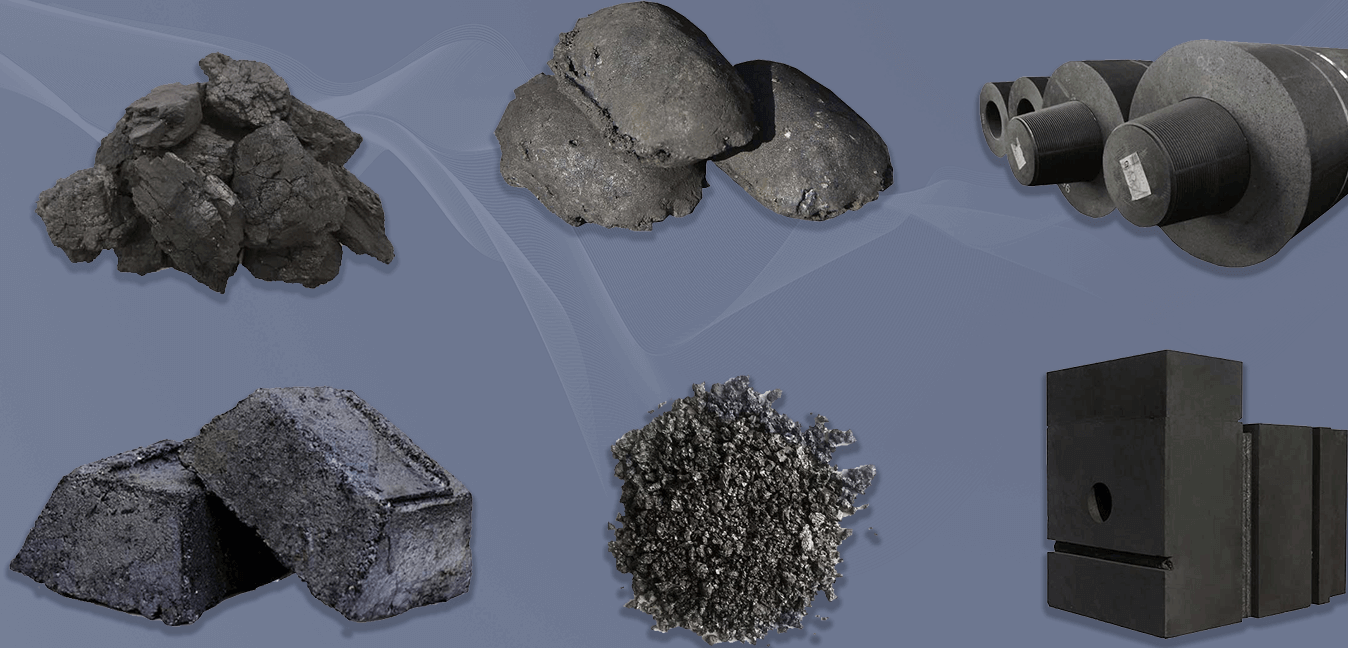

3. Many production processes. The production process includes raw material calcination, crushing and grinding, batching, kneading, molding, impregnation, graphitization and mechanical processing. Its production requires a lot of special mechanical equipment and kilns with special structures, the construction investment is relatively large, and the investment recovery period is relatively long.

4. A certain amount of dust and harmful gases are generated during the production process, and it is necessary to adopt perfect ventilation and dust reduction and environmental protection measures to eliminate harmful gases.

5. Petroleum coke and coal pitch are the by-products of the production and processing of petroleum coke and coal tar as the carbon raw materials required for production. The quality and stability of the raw materials are difficult to be fully guaranteed, especially for the production of high-power and ultra-high-power graphite electrodes. The use of needle coke, modified electrode pitch and special impregnant pitch with low quinoline insoluble content urgently needs the attention and active cooperation of my country's petroleum and coal chemical processing enterprises.

Comments

Post a Comment