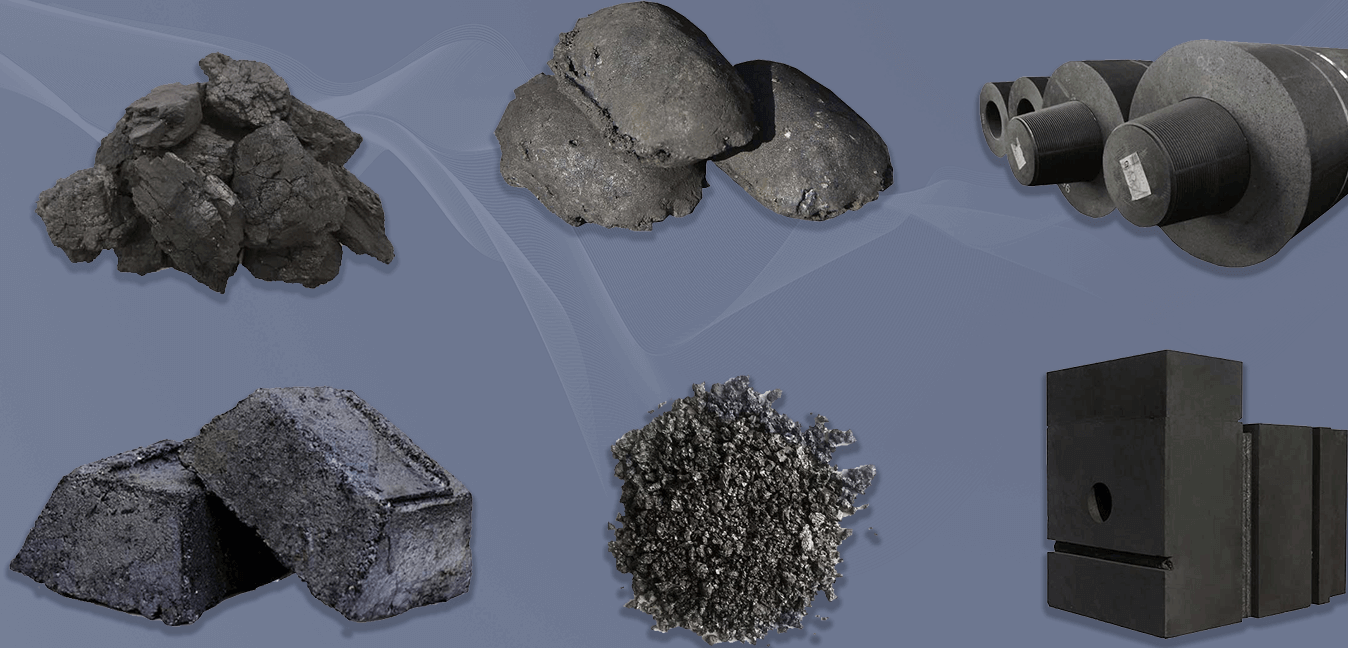

Self-baking electrode for submerged arc furnace

Electrode paste is called self-baking electrode in the smelting industry. It is called self-baking electrode because the process of baking into electrode is completed in submerged arc furnace by the heat of electric current.

Because of its uniform composition, low melting point, fast melting rate, and shortening of smelting time, electrode paste is receiving more and more attention from steelmaking enterprises and is hailed as a new type of material in the 21st century. It is mainly used for smelting in submerged arc furnaces. Pre-melted multifunctional refining slag has been used maturely in foreign countries, such as South Korea, Japan, Europe and the United States, etc., and has gradually attracted the attention and application of the domestic metallurgical industry.

The electrode paste produced by our factory is melted in an electric furnace, open hearth furnace, and cupola, with few impurities, stable and uniform composition, and can also be produced according to the chemical composition required by customers. Products with different content requirements such as high calcium, high aluminum, and high silicon can meet the index requirements of low sulfur, low carbon, and low phosphorus. Uniform particle size and consistent color.

The new type of electrode paste is composed of refined raw coal, desulfurizer, combustion-supporting agent and other materials. It is made through fine washing, desulfurization, and vacuum stirring mechanisms. It can be processed into goose-egg, trapezoidal and cylindrical shapes according to user needs. Shape and weight of bulk products.

The high-standard electrode paste produced by our factory has the following characteristics:

1. High cost performance, OEM processing is acceptable;

2. The ash content, volatile content, resistance and other indicators of the electrode paste can be customized;

3. Strict control of raw materials can ensure the stability of product quality;

4. Respond to the call of the country, update supporting environmental protection equipment, and return you a clear water and blue sky;

5. With 20 years of electrode paste production experience, we know more about electrode paste;

6. Make profit to end customers and achieve a win-win situation.

Comments

Post a Comment